Kraft och värme

Kraftverk genererar nödvändig el och värme till vårt samhälle, före både privat bruk och företag. Elen gör våra dagliga liv enklare, effektivare och bekvämare. Skjutspjällsventiler har en viktig funktion i kraftverkens system.

Upptäck mer

Skjutspjällslösningar för kraft- och värmeverk

Pålitliga avstängningslösningar på kraftverk bidrar till anläggningens effektivitet och de har också en viktig funktion utifrån ett hälso- och säkerhetsperspektiv.

För bottenaska är normalt sätt en metalltätande MV ventil anpassad för höga temperaturer det optimala valet. Det fina pulvret – flygaskan – samlas vanligtvis i silos innan det transporteras vidare tryckluftsystem och deponi alternativt vidareförädling. Skjutspjällsventilerna som används i den här typ av system måste kunna manövrera genom statiska mediapelare och ha ett rakt och slätt genomlopp utan kaviteter. Detta är precis vad HG ventilen erbjuder.

För koltvätt och stofthantering är MV en riktigt kostnadseffektiv lösning. Den är enkel att underhålla och dess skärande avstängningsteknik garanterar en säker och pålitlig drift.

I rökgasbehandlingssystem, som FGD-system, och hantering av slitande kalksten eller gipsslurry är Stafsjös slurryventiler det optimalt valet.

Rekommenderade produkter

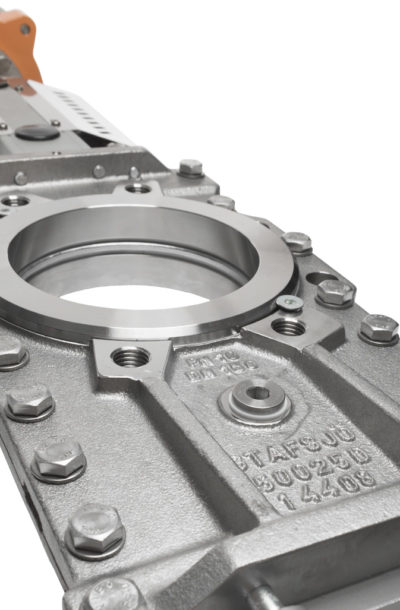

HG

Högpresterande skjutspjällsventil med genomgående spjällblad

HL

Lågtrycksventil med genomgående spjällblad

HX

En extrem högtryckventil med genomgående spjällblad

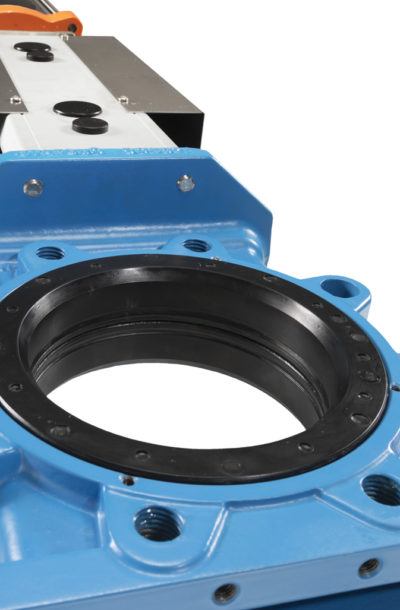

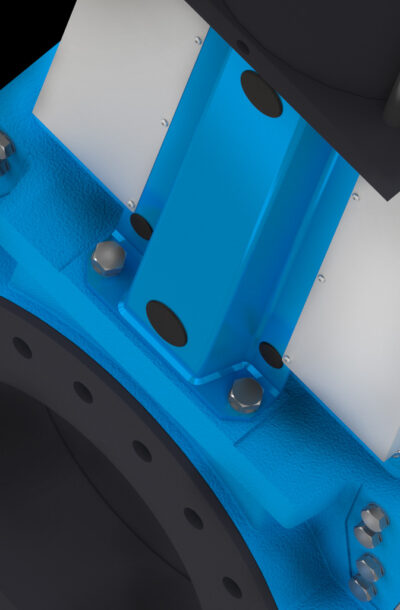

MV

Ensidigt tätande skjutspjällsventil för on/off eller reglering av både vätskor och torrt media.

RKS

En kvadratisk eller rektangulär helt rostfri skjutspjällsventil för pulver, bulk och avloppslam

SLV

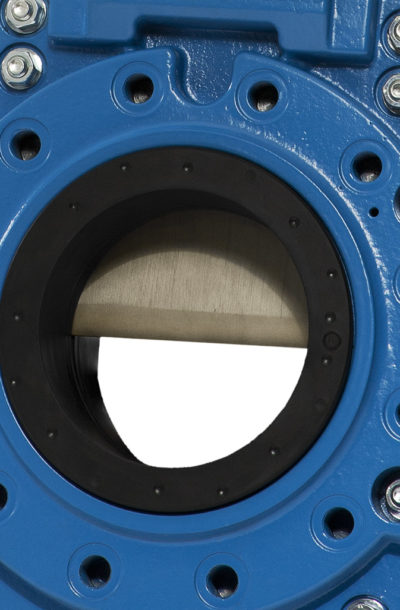

Kompakt och genomgående slurryventil

SLF

Robust genomgående slurryventil.

SLH & SLX

Genomgående högtrycksslurryventil

WB14E

Rostfri fulluggad och dubbelsidigt tätande skjutspjällsventil