Ensuring reliable isolation in the fishing industry

In the fishing industry, freshness and quality is crucial for consumer satisfaction. One innovative solution that has gained popularity over the last decades is the vacuum systems for transport of fish. These systems are designed to combine high efficiency with a gentle fish handling. Download case as pdf…

A vacuum system for fish handling system utilizes vacuum technology to transport fish. It can be used on land-based aquaculture systems to move live fish from one tank to another as the fish grow. These land-based systems are growing in popularity along with the demand of fresh fish from consumers. A more common application of vacuum technology is on fishing vessels where the fish are stored in tanks and later transported to land-based fishing industries for further processing.

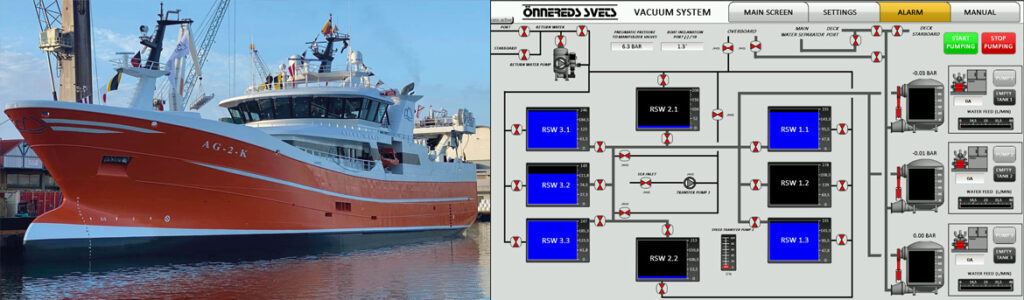

The vacuum systems are customized to each vessel. Önnereds Svets, based in Fiskebäck harbor in southwest part of Gothenburg, Sweden, have over 3o years of experience in vacuum systems for fish transport and they are used to adapt the systems according customer requirements. Their first vacuum system were introduced already in 1995.

Today’s fishing vessels offers all kinds of modern facilities and high-end automation systems. The quality standards are high while the project must be performed with a limited budget.

– At Önnereds, we have standardized on Stafsjö MV knife knife gate valve in our vacuum transport systems. The knife gate valve as a product line is optimal for us. It offers a full bore with good flow characteristics and it is reliable as it guarantee closure and a tight shut-off. Stafsjö offers an excellent mechanical solution, says Fredric Gustavsson, Project Manager at Önnereds Svets.

Fredric explains that they have used other brands historically, but due to quality concerns they decided to go all in with Stafsjö. Today they are able to support fishing vessels with stock products on the shelf of MV DN 300 and DN 350 for fast replacements or repair at the local harbor.

The sea water is challenging for almost any material. At Önnereds Svets, they have standardized on stainless steel EN 1.4404/316L for the tanks, pipes, flanges and valves with some components such as valve gates upgraded to duplex EN 1.4462. Just as the sea water is tough for almost any material, the equipment must stand up against the unpredictable sea weather without being deflected or malfunction. The installation areas are usually limited in space in all directions and the valves must accept installation in any direction.

The vacuum system and its overall components are made with special consideration for gentle fish handling. The fish are taken on board and stored in several large tanks below deck while awaiting the vessel to reach back to its harbor. Once the vessel has reached its final destination, it is time to activate the vacuum transport system. The fish are transported with negative pressure (-0,8 to 0 bar) from the storage tanks to the vacuum tanks. The negative pressure is kept to a minimum while the flow rate is closely monitored to avoid damaging the fish. The vacuum tanks automatically detect sufficient fish level using the latest radar technology. Once the desired level is reached, vacuum pump/tank switches to pressure (0 to 2,5 bar) to unload the fish to ondeck/onshore dewatering units or further to trucks or on-land based fishing industries.

The Stafsjö knife gate valves plays a crucial role in the systems: on the fish storage tanks, to ensure sufficient negative pressure, to isolate the transport system when needed and to control the flow of fish between the tanks.

About knife gate valve MV

Stafsjö’s knife gate valve MV can be used within a wide range of applications. It has a modular design and it can easily be customized with materials, actuators and automation accessories to meet different process conditions. It comes in stainless steel or nodular iron as standard, but is can also be supplied in a range of high-alloy materials such as duplex stainless steel and 254 SMO.

Önnereds Svets have standardized on the stainless steel MV with a duplex stainless steel gate, EPDM valve seat and the reliable SC pneumatic actuator unless hydraulic actuation is requirred. Other valve types commonly used in vacuum assisted fish transport systems is the full stainless steel Stafsjö WB14E knife gate valve.

About Önnereds Svets

Önnereds Svets was founded by Hans-Erik Pettersson and his son Erik Petterson in 1981. In the beginning, the business was mainly based on repairs of fishing boats. In 1992 Önnereds introduced their 1-tank vacuum system and in 1995 the 2-tank system were introduced for larger pelagic fishing vessels. In 2017 their first 3-tank system was delivered to Rockall vessel. This 3-tank system is Önnereds most demanded product offering today. In 2023 Önnereds expanded to land and delivered their first 3-tank system for transporting of live fish to Skagen land-based salmon farm. Find out more about Önnereds Svets on onnereds.se.