Chemical

Most of the manufactured products we use in our daily lives are dependent on products from the chemical industry. They produce important input to many other industries.

Discover more

Knife gate solutions for

the chemical industry

At Stafsjö we have the ability to tailor-made the knife gate valve you may need. We have solutions to comply with your ATEX requirements or demands on high alloy materials to resist harsh chemicals in your process systems.

The knife gate valve is often considered to be the optimal isolation valve for liquids with solids or fibers, often having a corrosive or abrasive characteristic. It can be related to phosphate fertilizer production utilizing the full bore and piggable HG knife gate valve for shut-off and isolation in applications prone to scale.

Some of our knife gate valves are also used for dry bulk and powder services, as for example PVC bulk production that benefit of HP knife gate valve to divert the bulk into different silos and the MV for isolation. In carbon black production, the valves have to operate in high temperatures making customized high temperature MV knife gate valves suited for the job.

Please feel free to contact us or any of our sales partners around the world for support.

Recommended products

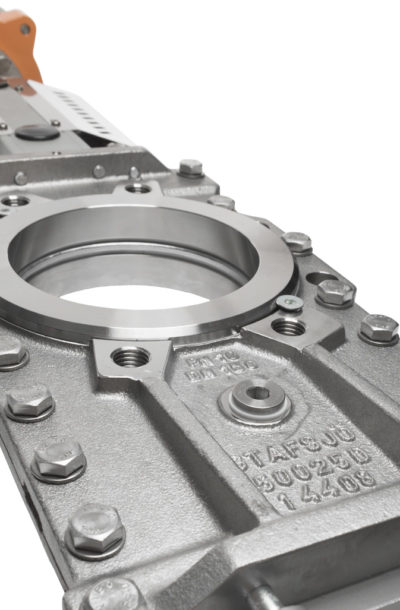

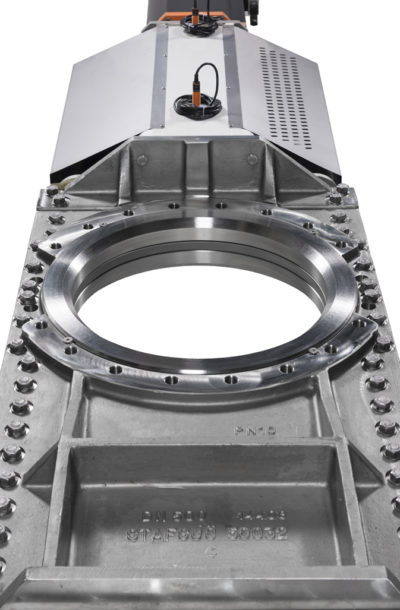

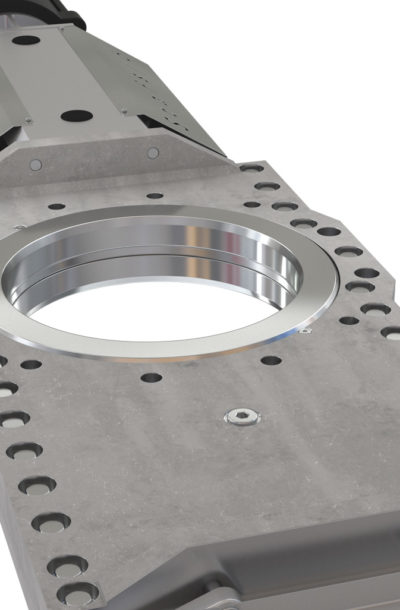

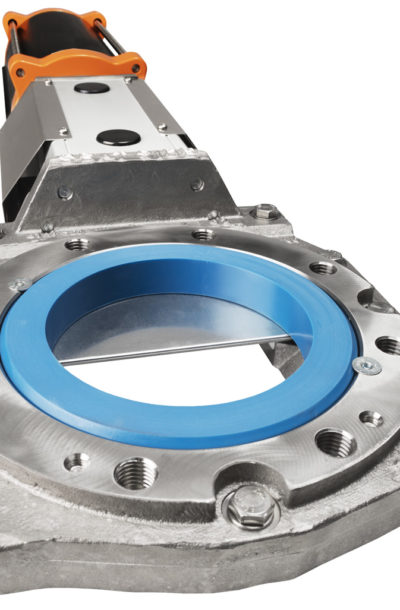

HG

High performance through-going knife gate valve

HL

A compact through-going knife gate valve for low pressure applications.

HP

Through-going high pressure knife gate valve

HPT

Through-going high pressure knife gate valve in Titanium.

HX

An extreme high pressure knife gate valve with through-going gate

MV

Uni-directional knife gate valve for on/off or control on dry media or liquids.

RKO

This is the optimal valve solution for junc traps and high density cleaners

RKS

A stainless steel square or rectangular knife gate valve for powder, bulk and waste water sludge.

WB14E

Stainless steel bi-directional and fully lugged high performance knife gate valve.