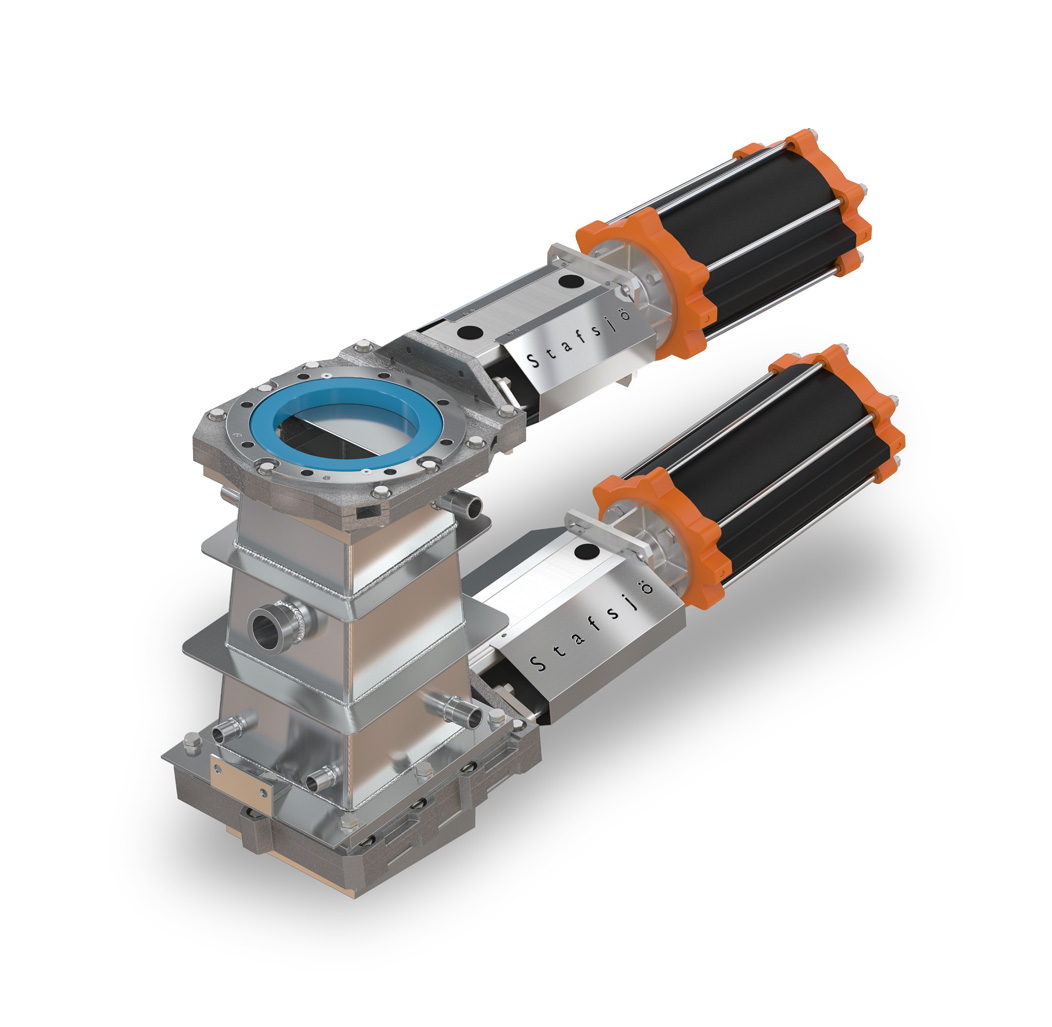

Junc Trap JT

A complete Junc Trap solution for reject separation

Available size range:

DN 100 - DN 200 / 250x250 (4" - 8" / 10" x 10")

Product data sheet:

Discover more

About JT

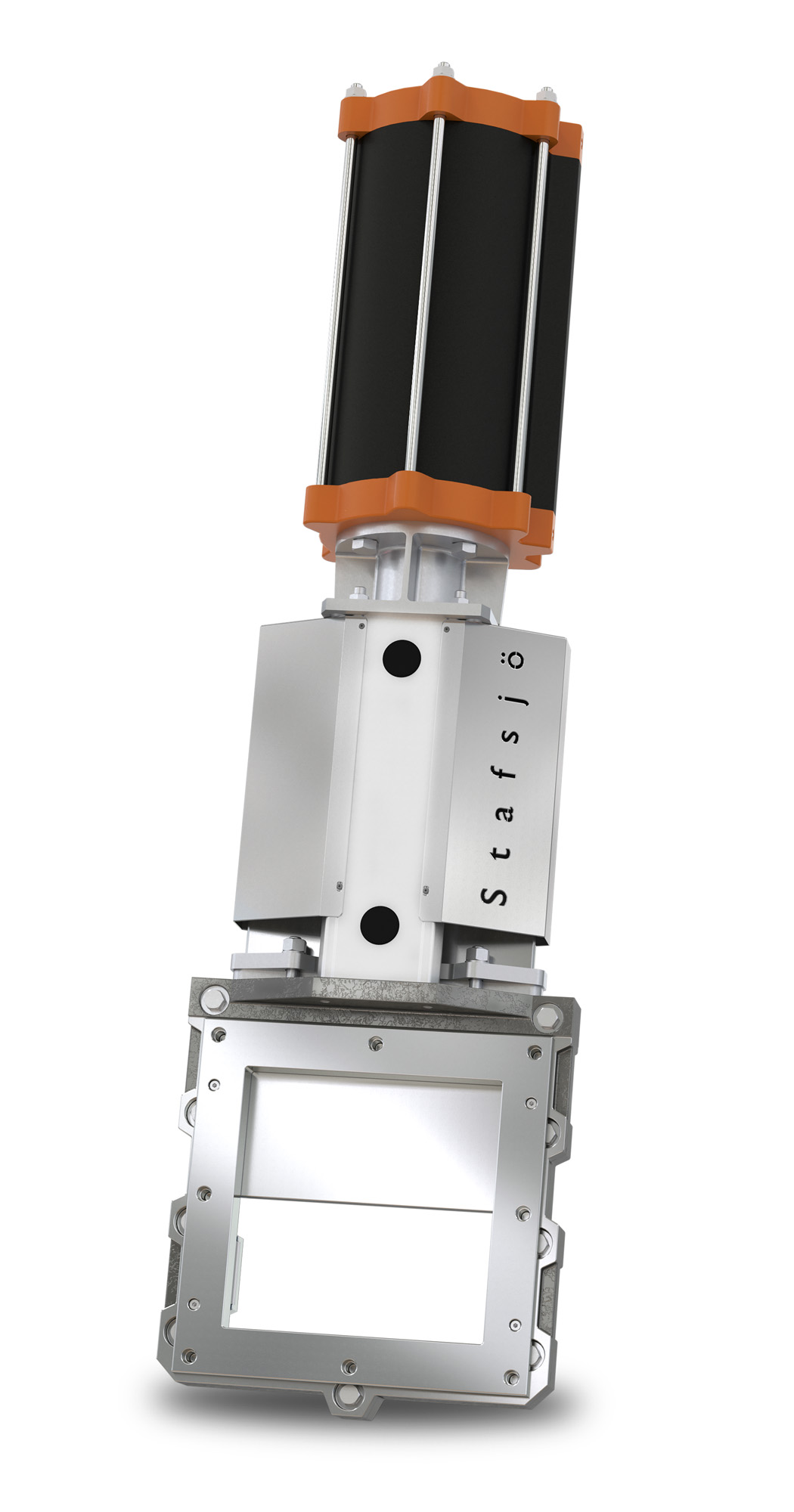

This is a complete solution for abrasive reject separation, primarly for HD cleaners in recycled fibre lines. The JT is specially developed to minimize turbulence, erosive wear and build-up of solids and reject materials.

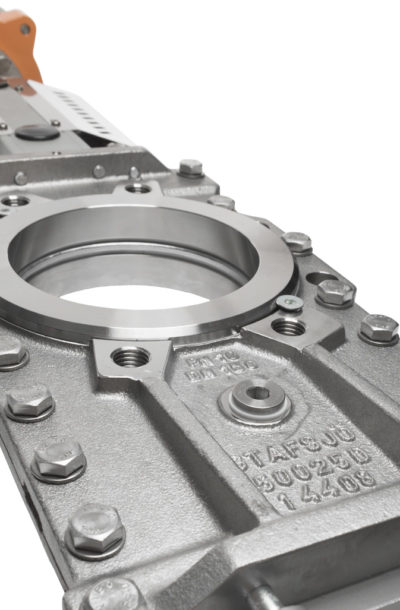

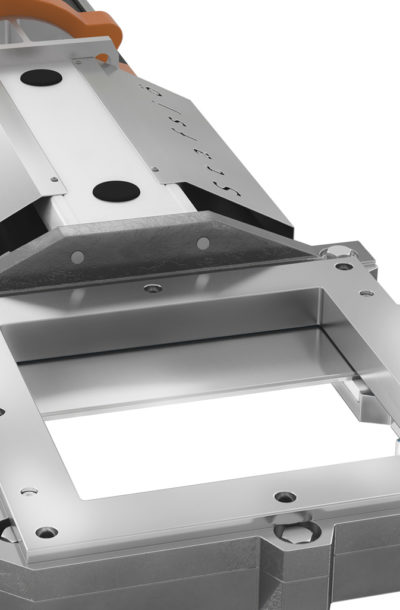

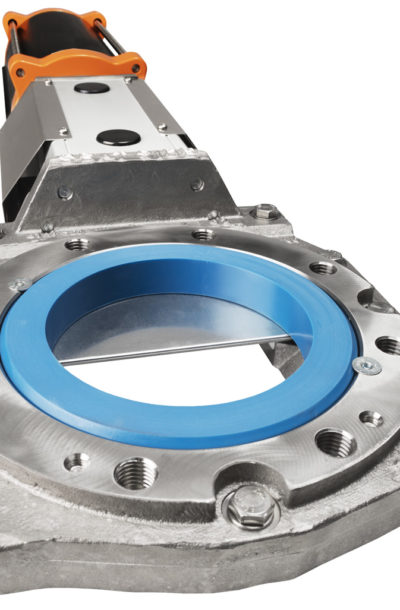

The JT consist of the RKO knife gate valve on the inlet side, which has a circular inlet and a square outlet, and the square JTV knife gate valve on the discharge side. Both valves are designed for tough operating conditions as standard with roboust valve bodies, high strength top works, hard chromed duplex gates and polyurethane seats to withstand the abrasive wear common in these type of applications.

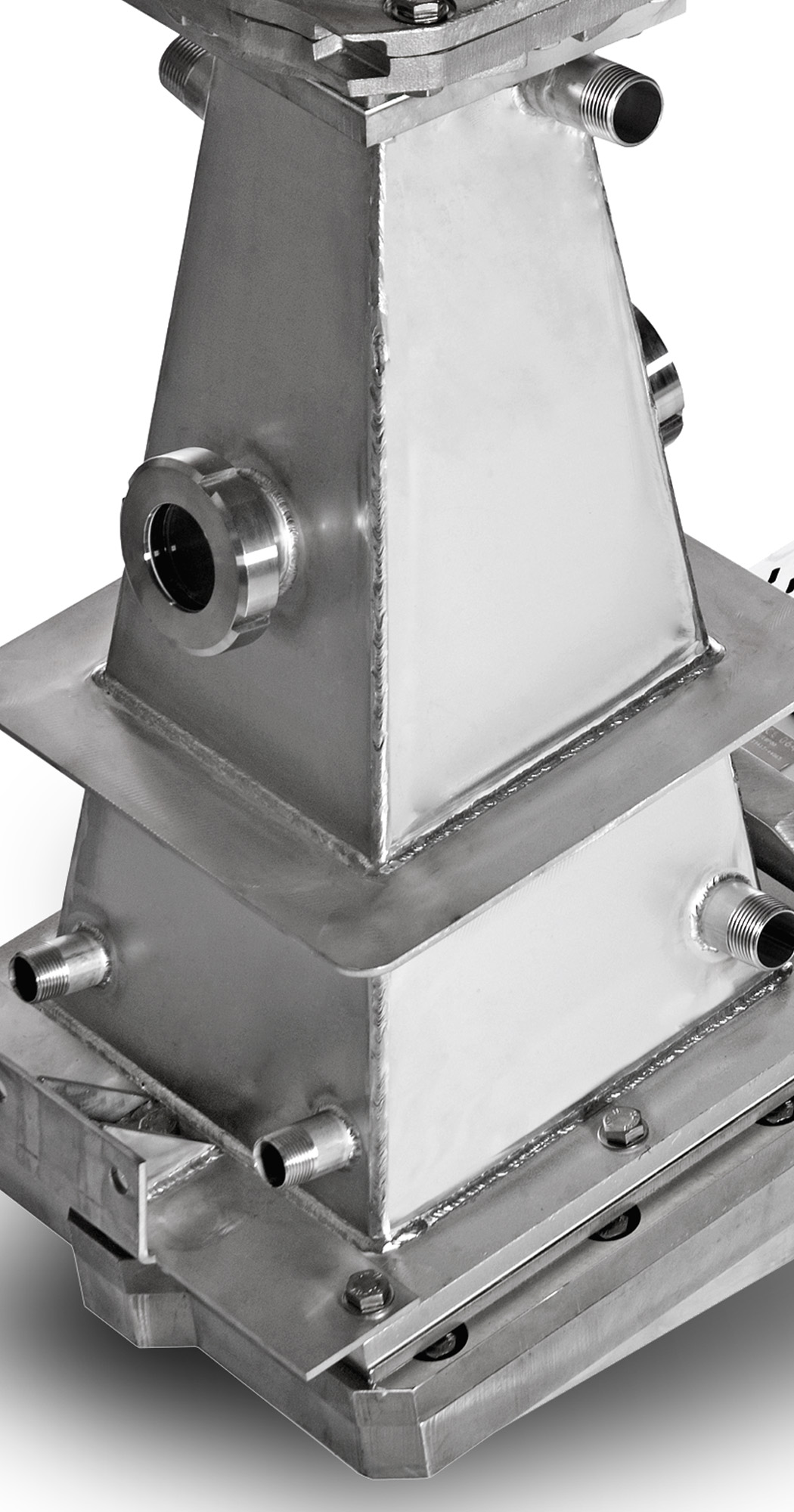

The reject tank enables different ways of operation. It is designed with two sight glasses for observation of the reject level in the tank. Water and air bleed connections are located near the top of the tank and three connections are located near the lower end in order to prevent possible clogging and congestions in dead corners.

Download the product data sheet for additional technical information.

Specifications

Shut-off technique

Uni-directional

Valve seat material

Polyurethane

Connection type

Fully lugged

Valve body material

Stainless steel

Industries

Biomass

Pulp and Paper

Product features

RKO as inlet valve

A reject tank for difficult and abrasive media

JTV as discharge valve

Downloads

- Title Format Size Restriction

-

Junc Trap JT

PDF 914 KB -

Knife gate valve RKO

PDF 2 MB -

Knife gate valve JTV

PDF 783 KB

- Title Format Size Restriction

-

Double acting pneumatic cylinder SC

PDF 1 MB -

Stafsjö standard accessories

PDF 4 MB

- Title Format Size Restriction

-

Knife gate valve specification guide

PDF 6 MB

- Title Format Size Restriction

-

Installation and service instruction

PDF 4 MB -

Maintenance instruction for RKO and JTV

PDF 641 KB