Knife gate valve

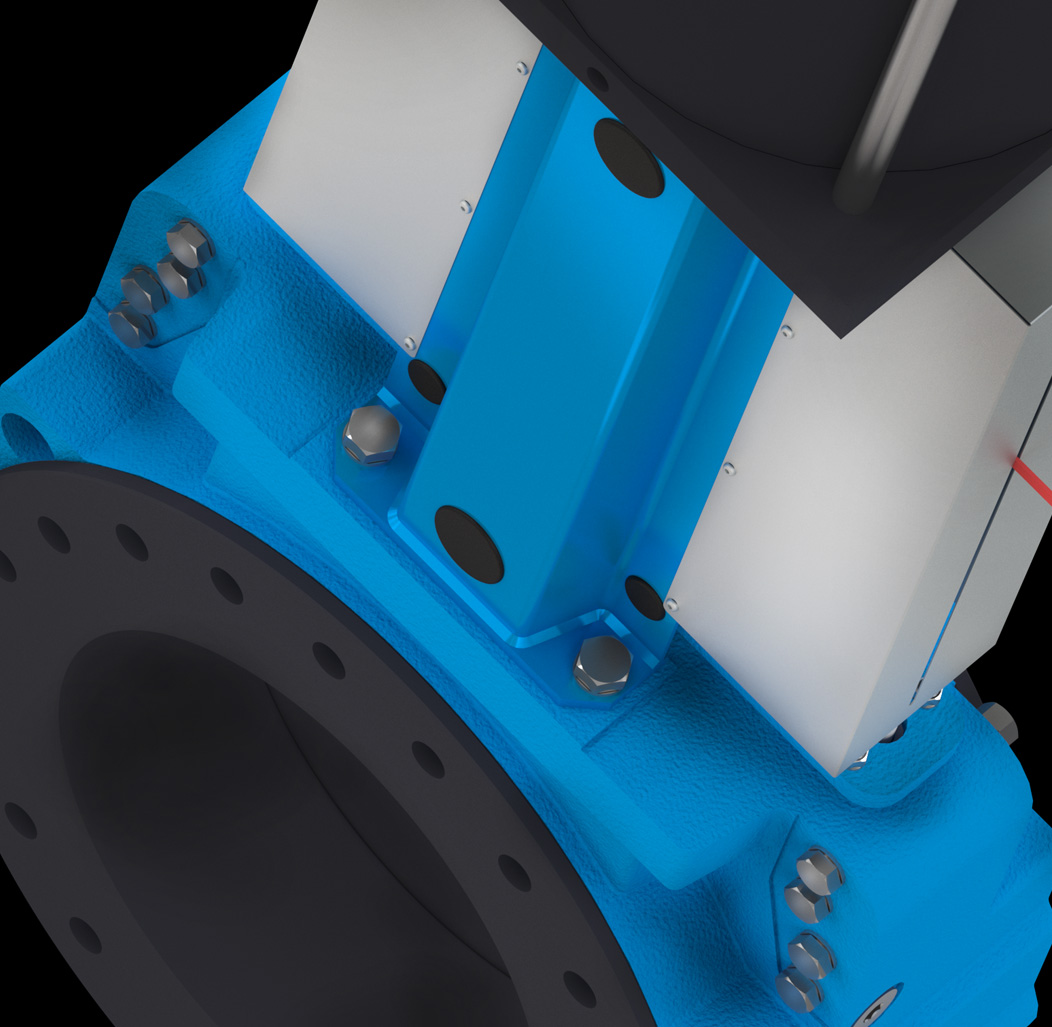

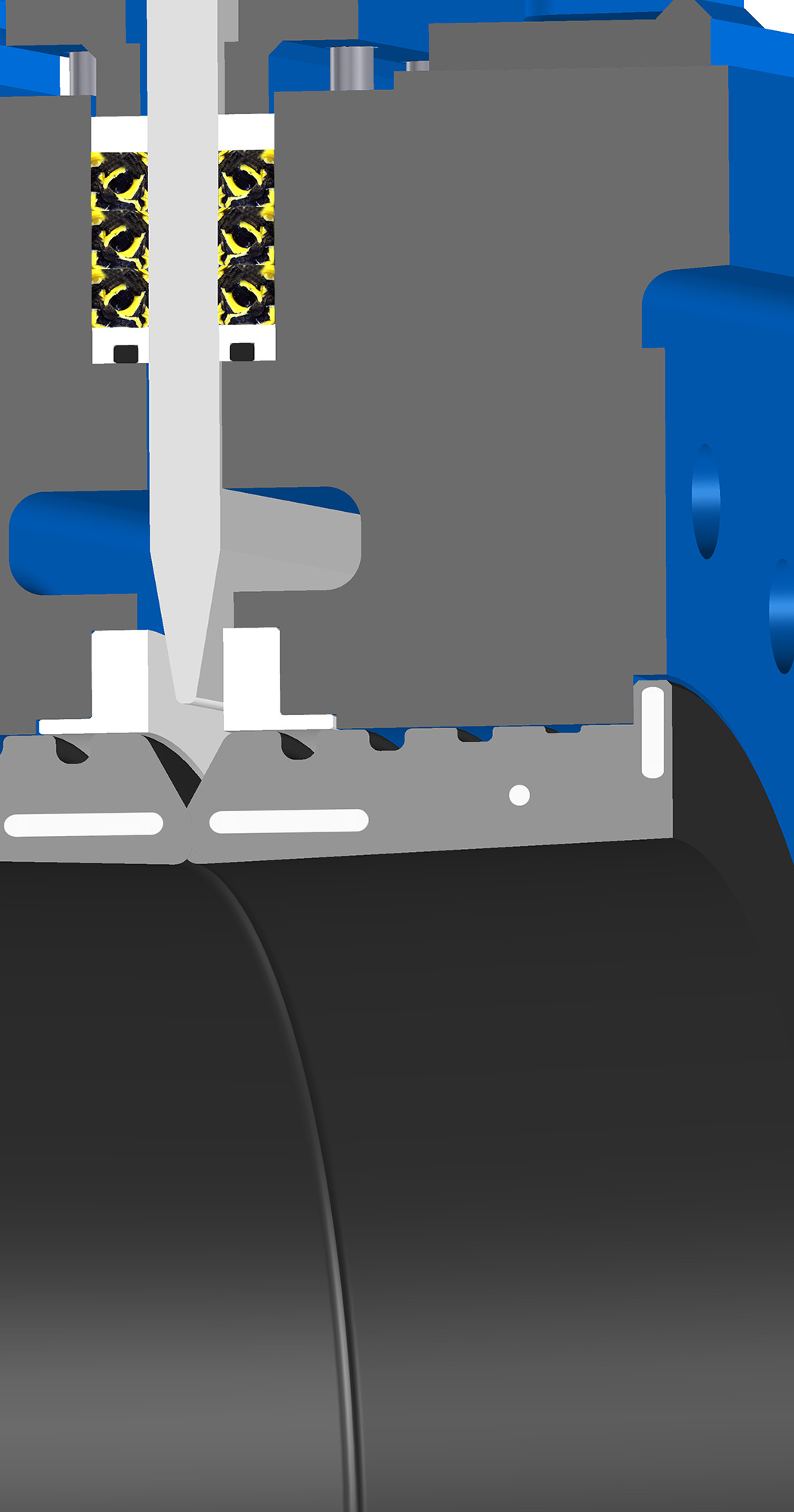

SLH & SLX

High pressure push through slurry knife gate valves.

Available size range:

DN 80 - DN 650 (3” - 26”).

Product data sheet:

Knife gate valve SLH and SLX Knife gate valve SLH and SLX (Imperial)

Discover more

About SLH & SLX

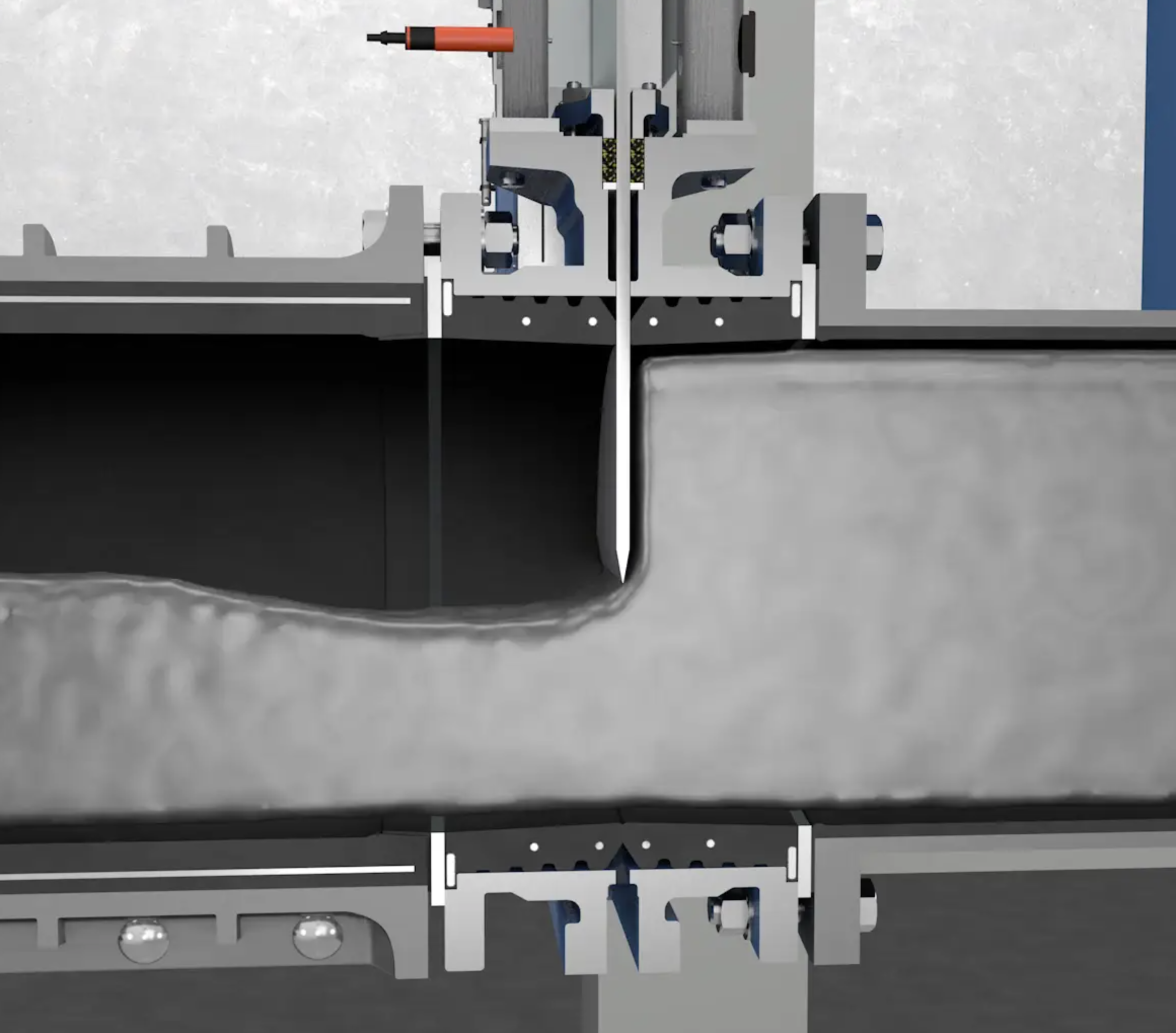

These push through slurry knife gate valves are designed to operate and provide bi-directional tight seal in high pressure and demanding mineral processing applications, typically slurry tailing systems.

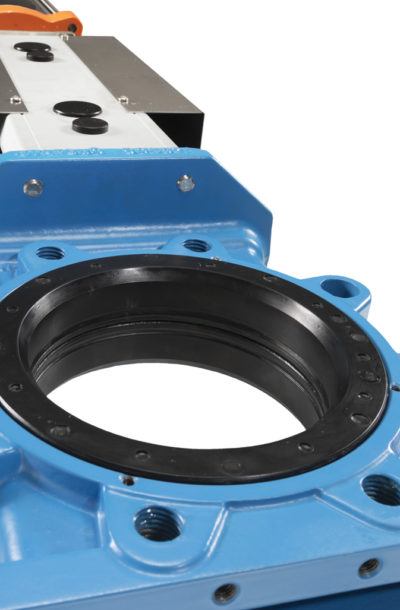

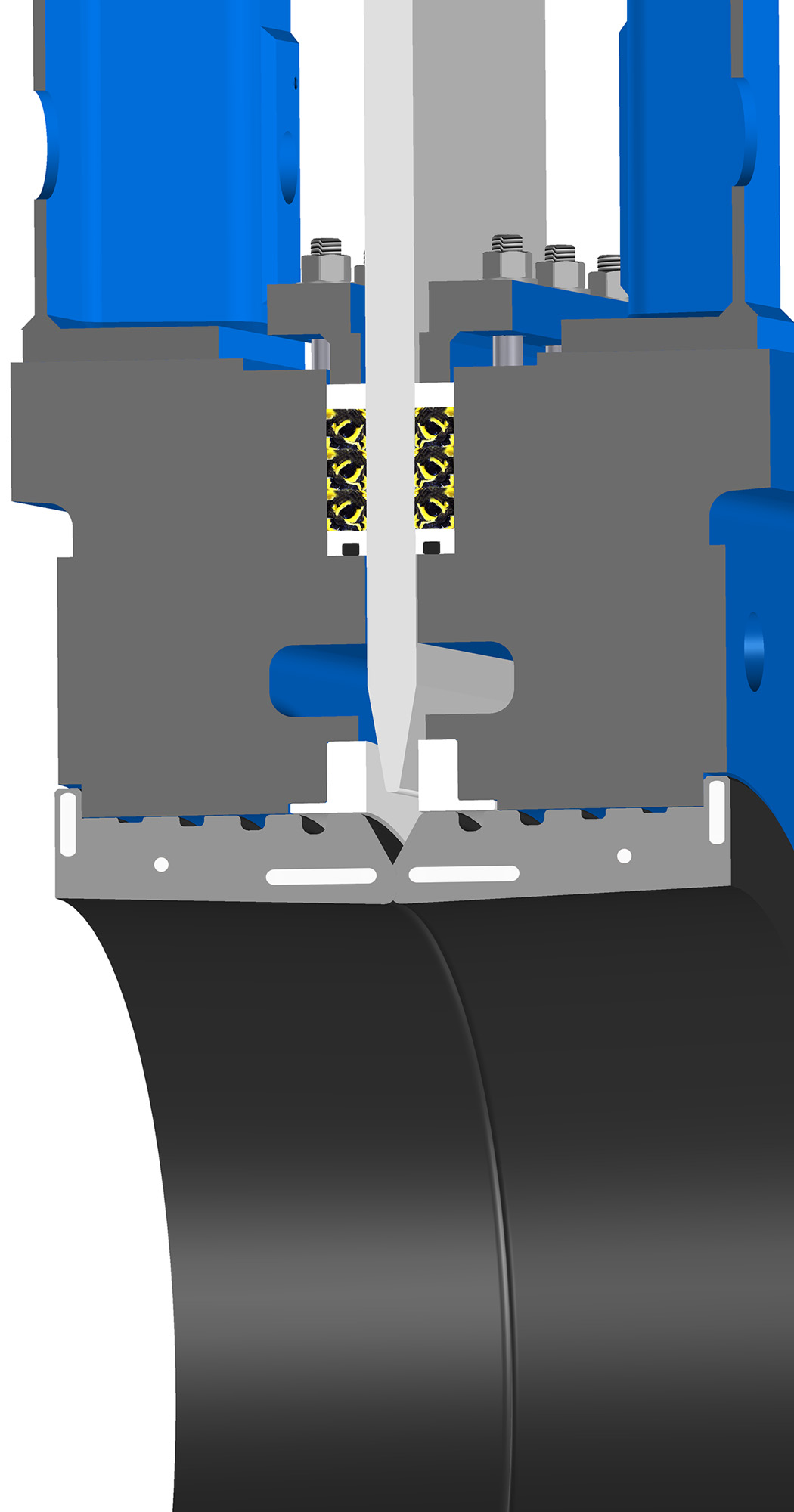

The SLH is designed to operate and provide a bi-directional tight seal up to 20 bar while the SLX has the features for 50 bar. They are modular designed and can easily be customized with actuators and related automation accessories to different process conditions. They are also available with mechanical lock out. As standard, the SLH and SLX comes with heavy duty, two-piece fully lugged valve bodies in nodular iron. Gates are provided in high strength stainless steel, special grinded and hard anti-stick coated with purpose of reducing friction when they cycle through the valves rubber seats.

In addition to these slurry valves, Stafsjö also offers the compact SLV up to DN 900 and another wide body slurry valve, the SLF, up to DN 800.

Download the product data sheet for additional technical information.

Specifications

Shut-off technique

Bi-directional

Push-through

Valve seat material

EPDM

Natural rubber

Connection type

Fully lugged

Valve body material

Nodular iron

Industries

Mining

Power

Product features

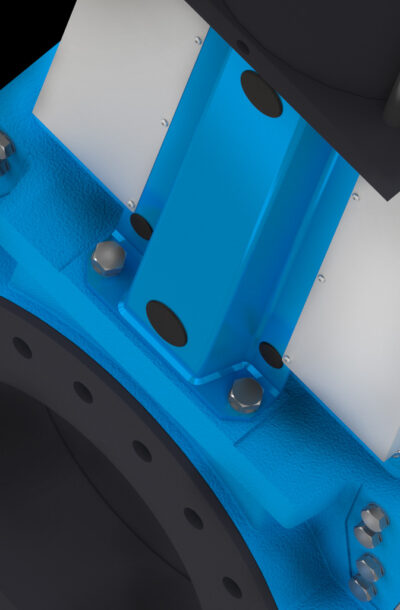

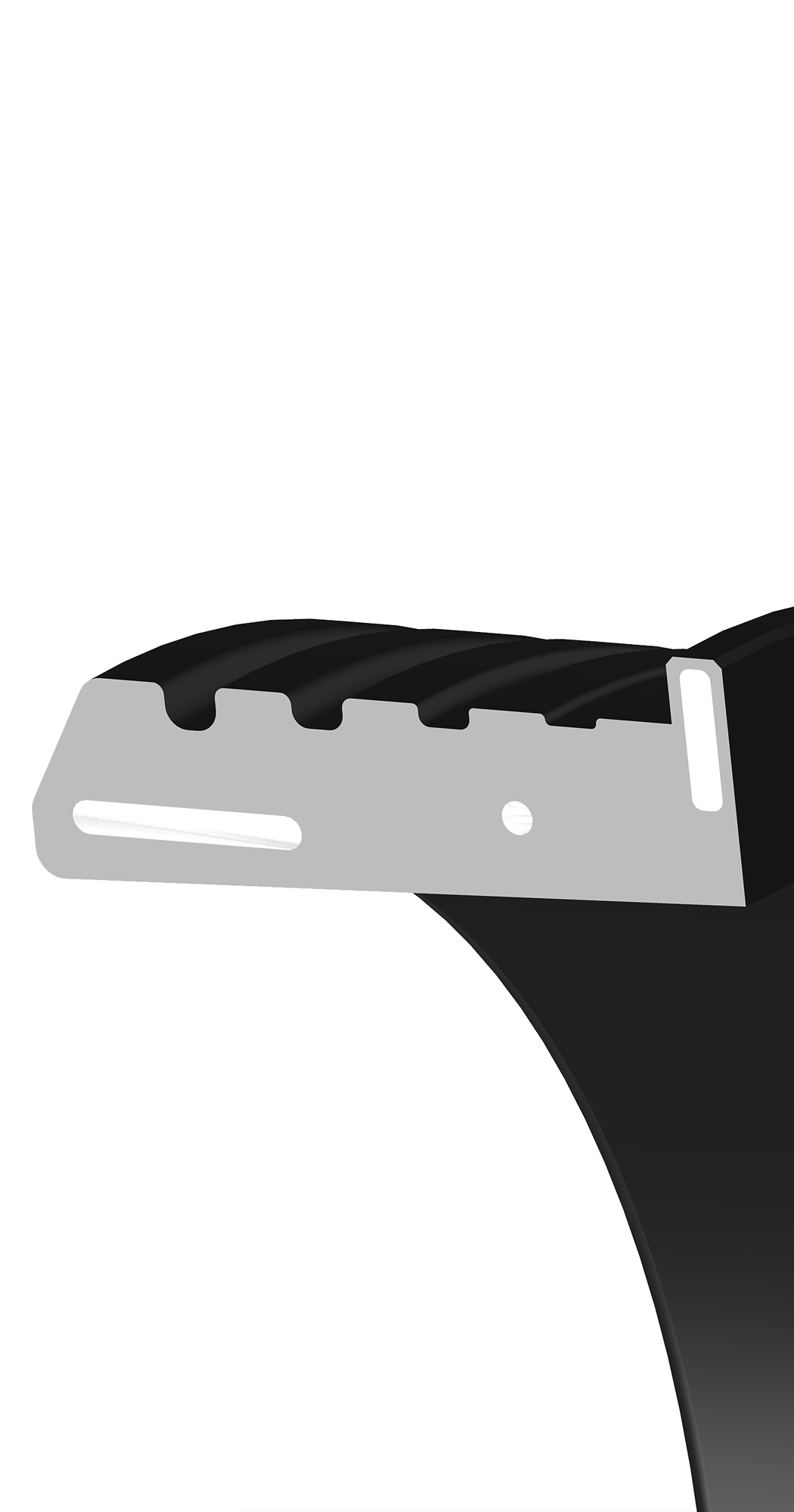

A precise gate alignment extend the service life

Reinforcements rings ensure stability and performance

Expansion areas reduce stress and actuation force

Downloads

- Title Format Size Restriction

-

Knife gate valve SLH and SLX

PDF 1 MB -

Knife gate valve SLH and SLX (Imperial)

PDF 1 MB

- Title Format Size Restriction

-

Manual actuators

PDF 2 MB -

Double acting pneumatic cylinder SC

PDF 1 MB -

Hydraulic cylinder

PDF 2 MB -

Electric motor AUMA

PDF 91 KB -

Stafsjö standard accessories

PDF 4 MB

- Title Format Size Restriction

- Title Format Size Restriction

-

Installation and service instruction

PDF 4 MB -

Maintenance instruction for SLV, SLF, SLH and SLX

PDF 380 KB