Stafsjö valves provide cleaner water

Clean water. The production is full running at the new Pålslund waste water treatment plant in Värnamo municipality, Sweden. One of the most modern around the Baltic Sea. This is a unique project where suppliers are subject to the highest demands. No less than 230 of Stafsjö’s knife gate valves can be found in the facility. Each and every one from Stafsjö, that scores the highest rating for its flexibility.

Demands placed on sewage treatment plants continue to increase. But so too does the necessity of returning the water used by households and industry to nature. A purity of the highest order must be attained, enabling our ecosystem of microorganisms residing in watercourses to continue working. This is a responsibility that we all share.

Quality in focus

– We quickly realized that it is better and easier to build a new plant than to patch up our old installations, especially if should meet the demands required of us. Here we have a system that is designed with functions that we can easily control and manage. Pålslund is unique, says Ulf Nilsson, Water & Drainage engineer at Värnamo municipality.

This set high demands on all equipment. From a mechanical point of view, it is a large and complex project. The specification requirements are clear. The valves used must be fully up to the job. This is of particular importance because the sewage treatment plant in Värnamo is controlled and managed on-line.

Value for money

At every turn a Stafsjö valve can be seen, often several per section. Yet their implementation is a science in itself. A completely new pump station has been built down in the centre of Värnamo. With its impressive capacity, 1,600 cubic meters of waste water per hour pumped 40 vertical metres over a distance of 6 km up to the waste water treatment plant located just outside the town.

– Stafsjö is a natural choice for us, says Håkan Wennerhag at the construction company, Malmberg.

– In terms of quality, these are excellent products and I cannot find anything ‘comparable’. Stafsjö may not be the cheapest but they always meet the highest standards and have a support organisation that is fast and steps up to the mark. These are affordable, reasonably-priced valves for the money.

Sizeable installations

Down in the pumping station, 10 metres below ground, a huge hall can be found. Here it is difficult to even embrace the tubes with open arms. The valves from Stafsjö are also sizeable.

– One might think that we have exaggerated. But the last plant lasted for 40 years. Here we have planned for a longer life span and the increasingly high demands placed on purification. This is why we have equipped the plant with components, control systems, piping, pumps and valves that meet these requirements, says Ulf Nilsson.

Those municipalities and operators which do not meet the increasingly stringent treatment requirements for nitrogen risk large fines and penalties.

Smooth operator

Leachate from the Stomsjö landfill and waste dump is also transferred to the Pålslund wastewater treatment plant. Three additional municipalities in the region, which up until now have had their own treatment plants, will be connected to the plant in the near future.

In the planning phase the dialogue with suppliers, as well as establishment of parameters such as price, quality, deliverability and performance, are all crucial.

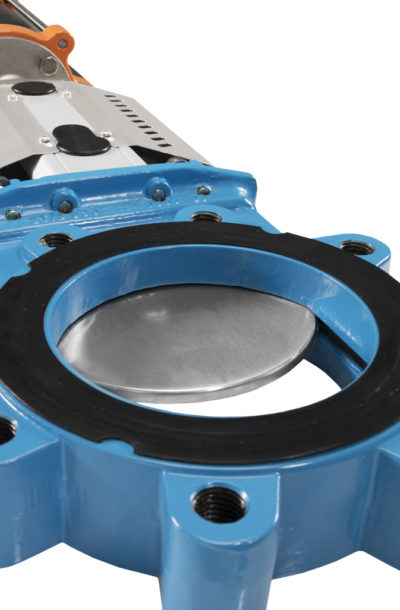

– For me, Stafsjö is synonymous with safe and secure delivery, says Håkan Wennerhag at Malmberg Water. We wanted and needed 230 units, fully lugged type, bolted from both sides, for the sewage treatment plant in Värnamo. Stafsjö was out in front. We got a really good service and they did not let us down at any time.

Serve as a model

A number of situations arose during the construction period. When changes were made on the pipe sizing, Stafsjö managed to squeeze in additional orders in the middle of their production schedule, just to ensure they fulfilled the supply obligations.

– We are very satisfied. Whenever we needed any customizations of any components they, in principle, came with the return delivery. They are as committed to the final delivery as we are. So this is not the last time we will contract Stafsjö, adds Håkan Wennerhag who also took valves from Stafsjö with him to the sewage treatment plants in St: Petersburg, Russia, and Klaipeda in Lithuania, both in need of upgrading.

Värnamo municipality with the Pålslund facility will serve as a model. This is a plant that represents a major step forward for the technology in waste water treatment.

Further information

Please feel free to contact Stafsjö on sales@stafsjo.se or on +46 11 39 31 00 for any questions on valve solutions for water and waste water.